Introduction

Quality control is a critical consideration in transistor distribution, as the quality and reliability of components can have a significant impact on product performance and overall business success. In this article, we will explore quality control best practices for transistor distributor, including establishing quality control procedures, ensuring component authenticity, implementing testing and inspection procedures, monitoring and evaluating performance, and industry best practices for quality control.

Establishing Quality Control Procedures

Establishing quality control procedures is critical to ensuring that high-quality components are distributed to manufacturers. This includes establishing a quality control program that includes key components such as incoming inspection, in-process inspection, and final inspection, as well as ensuring compliance with industry standards such as ISO 9001.

Ensuring Component Authenticity

Counterfeit components are a common problem in the electronics industry, and can have a significant impact on product performance and reliability. Transistor distributors should have strategies in place for ensuring component authenticity, including working with trusted suppliers, implementing component traceability programs, and identifying and addressing potential issues.

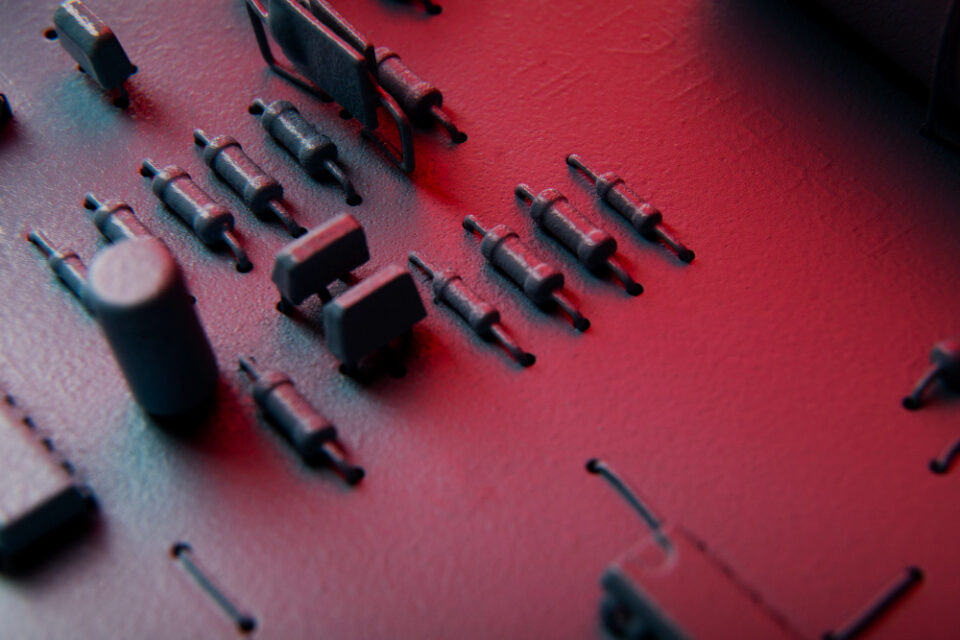

Implementing Testing and Inspection Procedures

Implementing testing and inspection procedures is critical to ensuring that components are accurately and reliably tested and inspected prior to distribution. This includes implementing common testing and inspection procedures such as electrical testing, visual inspection, and dimensional inspection, as well as ensuring accuracy and reliability in the testing and inspection process.

Monitoring and Evaluating Performance

Regularly monitoring and evaluating the performance of quality control procedures is critical to ensuring that high-quality components are distributed to manufacturers. This includes establishing performance metrics, regularly monitoring and evaluating performance, and making adjustments as necessary to ensure that the quality control program is meeting the needs of the business.

Industry Best Practices for Quality Control

There are several industry best practices for quality control in transistor distribution, including establishing a quality control program that includes incoming inspection, in-process inspection, and final inspection, ensuring compliance with industry standards, working with trusted suppliers, implementing component traceability programs, and implementing common testing and inspection procedures.

Conclusion

Quality control is a critical consideration in transistor distribution, as the quality and reliability of components can have a significant impact on product performance and overall business success. By establishing quality control procedures, ensuring component authenticity, implementing testing and inspection procedures, monitoring and evaluating performance, and following industry best practices, transistor distributor can ensure that they are providing high-quality components to manufacturers. By prioritizing quality control, transistor distributors can build trust with their customers and support the success of their business in the competitive electronics industry.